Industrial sewing machine

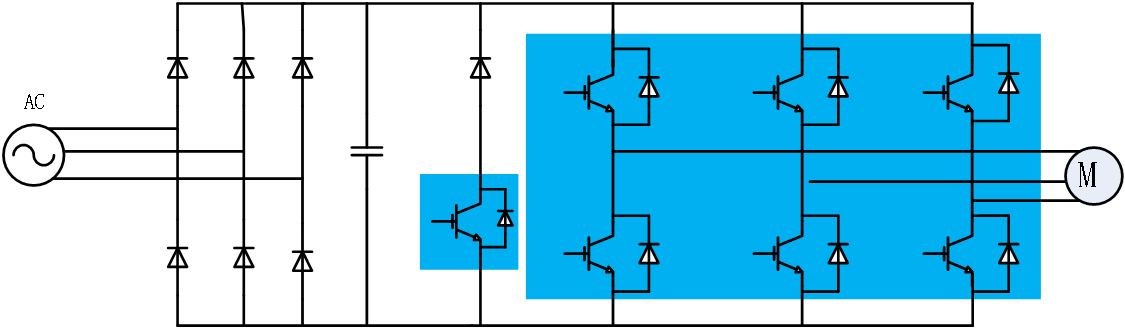

In recent years, the rapid development of China's clothing processing industry has caused a shortage of industrial sewing machines. However, with the rise of labor costs and other factors, processing enterprises have put forward increasingly high requirements for the performance of industrial sewing machines. At present, industrial sewing machines with permanent magnet synchronous motors as the mainstream power unit are rapidly occupying most of the market. Compared with traditional clutch motors, permanent magnet synchronous motors have advantages such as small size, good dynamic performance, convenient control, and high power density. The basic control process is as follows: DSP determines the current position of the rotor and calculates the current speed of the motor based on the captured Hall position signal, and calculates the effective values of each PWM output channel through vector control algorithm and PID algorithm. The output PWM is driven by the chip to turn on the corresponding IGBT, causing the corresponding winding of the motor to rotate continuously in the given direction through current.

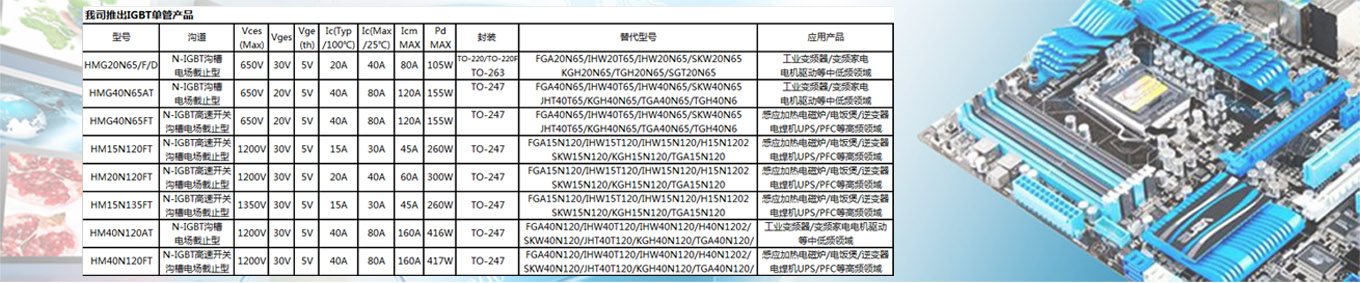

Hongmei utilizes Trench Field Stop IGBT technology and adopts high-density device structure design and advanced ultra-thin chip processing technology to launch a new generation of Trench FS IGBT series products. This series of products significantly reduces device saturation voltage drop and turn off loss by optimizing carrier injection efficiency and carrier distribution, thereby reducing device power consumption and improving system efficiency.